Non-destructive testing in construction (NDT)

for building condition analysis and inspections

We provide structural safety tests

After a magnetic stray field measurement by night (prestressing steel breakage detection) on the Sunshine Skyway Bridge in Florida (USA): from left to right, Graduate Engineer Simon Knapp, Professor Bernd Hillemeier, and B.Sc. Thomas Luther

The practical implementation for non-destructive testing methods, such as the remanent magnetism method, is one of our core services. There are specific non-destructive testing methods available for the investigation of structures. Each method allows an evaluation of the existing structure in terms of stability and safety.

Our projects’ primary objective in the field of non-destructive testing, in Germany as well as on an international level, is to verify the safety of building structures. We use various non-destructive testing methods, e.g. thermography, ultrasonics, radar technology and magnetic as well as inductive methods.

In case that non-destructive testing has to be carried out in heavily frequented traffic, the affected roadway areas can be inspected by means of night measurements using a temporary partial road closure.

Non-destructive testing for structural repair

Structural repair is gaining in importance within the context of the preservation and upgrading of existing buildings, as it frequently turns out to be more economical than a newly constructed building would be. In order to plan corrective maintenance work, the condition of a building’s structure must be recorded. For this purpose, various non-destructive or non-destructive testing methods are used. The condition analysis forms the basis for any execution planning.

Magnetic stray field measurement at the Hunte Bridge using a bridge inspection unit

The IFDB (Ingenieure für das Bauwesen, i.e. Civil Engineers – Prof. Hillemeier & Knapp GmbH) specializes in non-destructive testing (NDT) in construction. These include conventional and special non-destructive testing methods, such as magnetic stray field measurement, ultrasound technique, radar technique, magnetic induction, and chemical-physical methods for stability determination and corrosion detection.

Our special focus lies on the non-destructive location of fractures in the tension reinforcement of prestressed concrete components by means of stray magnetic field measurement (also known as prestressing steel breakage detection and remanent magnetism method), both in the active as well as in the remanent magnetic field.

Our knowledge in this field is based on more than 30 years of measurement experience as well as on five dissertations. Testing devices of various sizes are available to test virtually any prestressed concrete component non-destructively.

In the context of DIN 1076 (“Engineering structures in connection with roads – inspection and test”) and the “Richtlinie zur Nachrechnung von Straßenbrücken im Bestand”, the non-destructive test method of stray magnetic field measurement provides conclusive measurements that confirm stability statements which are otherwise only gathered on a statistical basis.

Our reference lists show various non-destructive test operations: prestressing steel breakage detection, localization of tendons embedded in reinforced and prestressed concrete, determination of concrete cover, detection of honeycomb locations and hollow sphere structures as well as the determination of concrete compressive strength.

Brochure: Magnetic Flux Leakage

Brochure about remanent magnetization

Downloads for the Remanence Magnetism Method

The PDF downloads address the following questions, among others:

- What is a magnetic stray field measurement?

- Why do prestressing steels fail?

- What measurement technology is used in the tests?

Every measuring operation shows:

Almost every test is characterized by specific characteristics. Therefore, experienced and highly qualified personnel with decision-making authority is indispensable for on-site measurements.

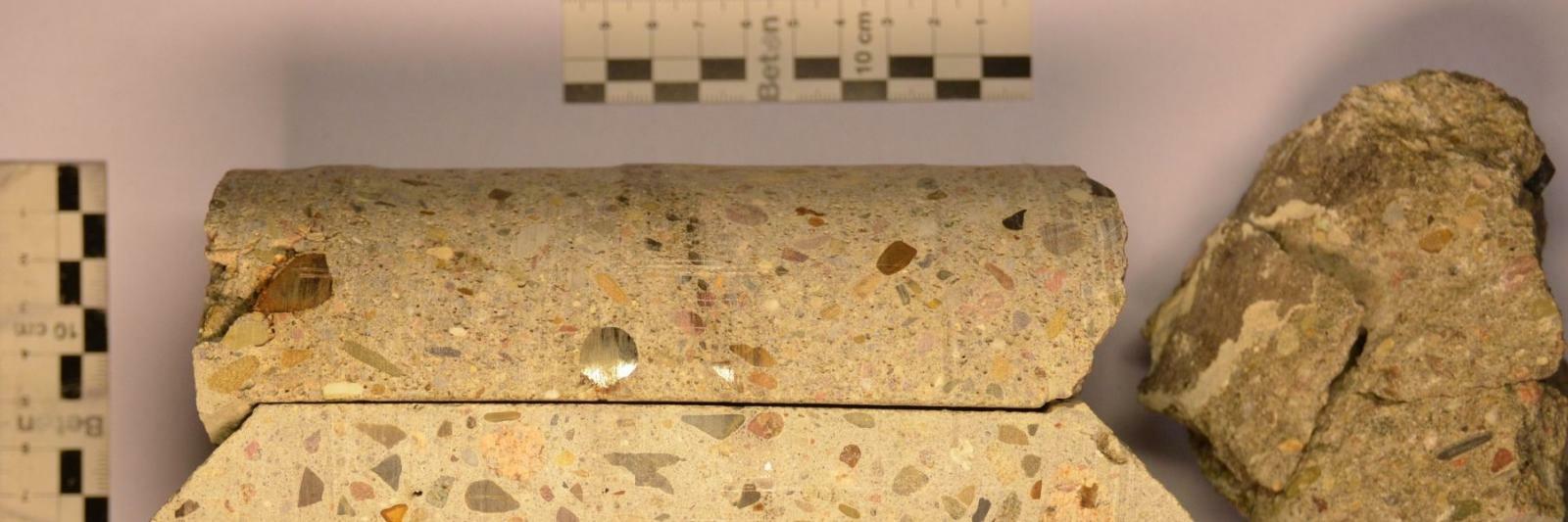

Non-destructive test with our smallest MobiRem measuring unit (REM 40) on a girder of a highway bridge

Prestressing steel breakage detection with remanent magnetism (NDT)

Cracks and fractures: Pre-stressing steel can crack due to external influences (de-icing salts) or develop production-related stress corrosion cracking

Objectives of prestressing steel breakage detection: The non-destructive prestressing steel breakage detection method allows the localization of cracks and fractures in pre-stressing steels embedded in concrete constructions both in the immediate bond (prefabricated components) as well as in crimped clad tube.

Advantages of the test procedure:

- A detection of the tendon profile, with e.g. a ground penetrating radar, is not required for areal investigations (measurements with the REM 150 and REM 350)

- The imaging representation of results allows an immediate defect detection

Procedure

- Magnetization of the prestressing steel: To generate high quality measuring data, the prestressing steel is non-destructively magnetized to remanence.

- Measurement data evaluation: Immediately after the measurement, a first evaluation of the tendons condition is possible by means of a special measuring software.

- Report – Expert Opinion: The measured data are additionally examined analytically for intricacies and presented in an inspection report with explanations.

Non-destructive magnetic stray field measurements are suitable for the following structure types: roof constructions, bridge constructions (transverse tendons in bridge decks or tendons in bridge girders), ceiling constructions (parking level floors) and prestressed concrete tanks

Other Non-Destructive Testing (NDT) methods

- Radar measurement to evaluate the supporting structure of concrete buildings

- Radar measurement and inductive measuring methods for reinforcement location

- Ultrasound to determine dimensions of concrete components or compaction defects

- Thermography to localize plaster detachment and defects in concrete or to find former doors or masonry joints under plaster

The benefits of non-destructive building investigations:

- Creation of planning security so that reliable data can be obtained from the examinations, even if construction plans are no longer available

- Schedules compliance assistance

- Safe residual use of the building so that the load bearing reserves can be reliably determined in case of a planned conversion

- Cost savings by means of detailed investigations: selective renovation instead of replacement

- Marked building components for easy comprehension of the results (e.g. the location of reinforcement before drill core extraction)

- A first rough evaluation on location is possible right after the (non-destructive) measurements

Special concrete chalice supports on the construction site of the Stuttgart 21 railway project

Special Concrete

- Development of special concrete formulas for extreme stress conditions caused by acids, bases, sulfates and chlorides (sewage systems, cooling towers, shafts, tanks, silos)

- Extreme protection by thin glass coating (Glass-Lining)

- Crack-free concretes with regard to temperature changes and shrinkage

Quality Management

- Planning, implementation, execution, and consultation for construction projects for quality assurance (QA manual, QA plan)

- Basic evaluation of technical and economic key questions

- Development of planning concepts